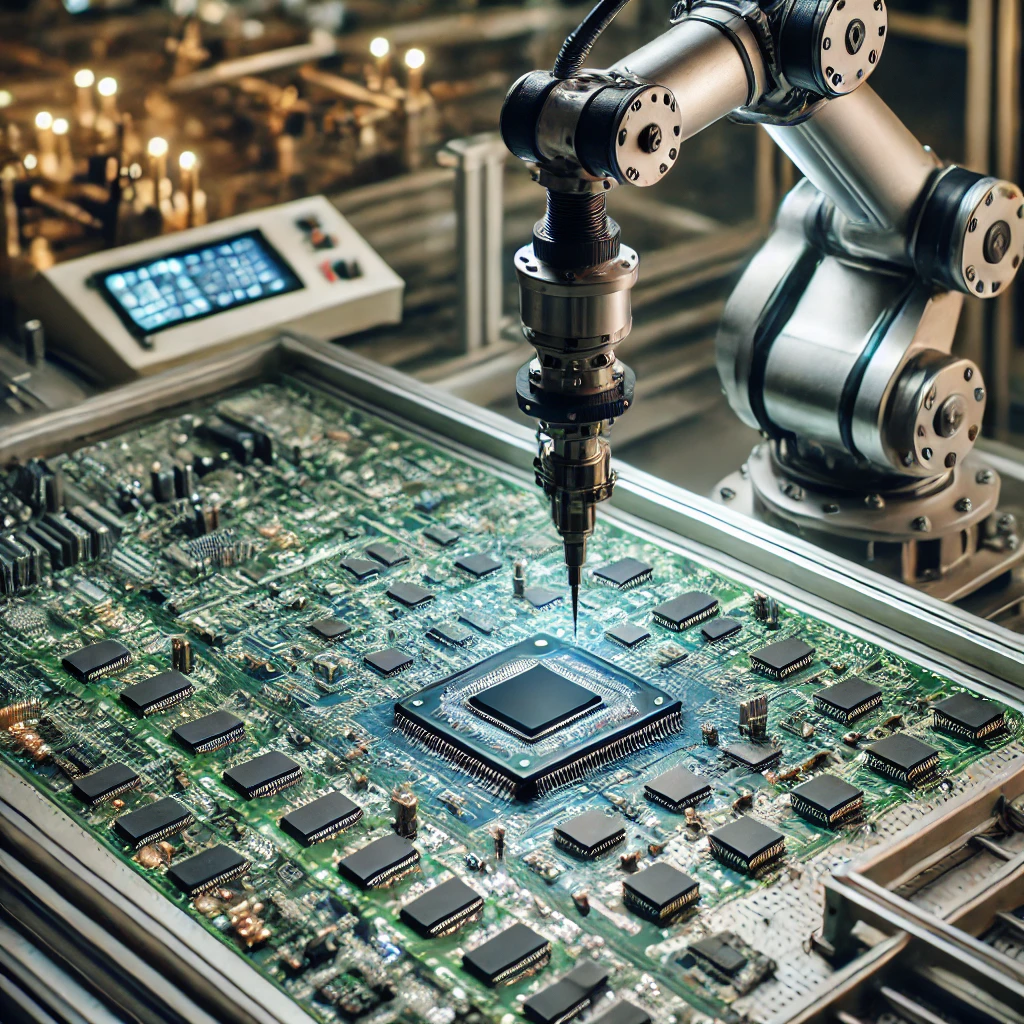

1. Automatic IC Mounting

Integrated circuits (ICs), which control the operation and function of the LED lights, are automatically placed on the PCB. This is typically done using a pick-and-place machine that precisely positions the ICs according to the circuit design.

This step is crucial as ICs are responsible for managing the input and output signals to the LEDs, ensuring that the screen displays images correctly and uniformly.

2. Mounting LED Beads

LED beads, or chips, are then placed on the PCB in predetermined locations. This task is also performed by automated pick-and-place machines that handle the tiny components with high accuracy and speed.

The placement of LED beads must be precise to ensure consistent color and brightness across the entire display. This step is critical in defining the pixel pitch (the distance between the pixels), which directly influences the resolution of the display.

3. Reflow Soldering

After placing the ICs and LED beads, the entire assembly undergoes reflow soldering. This process involves passing the assembled PCB through a controlled oven where solder paste (previously applied to the board during the placement of components) melts and solidifies, creating permanent solder joints.

Reflow soldering is essential for creating reliable electrical connections and mechanical strength between the components and the PCB. It must be carefully controlled to prevent defects like solder bridges or cold joints.

4. Screwing

Following soldering, screws are added to the assembly to secure heavy or larger components in place and to attach the PCB securely within the module frame.

This step ensures the structural integrity of the module, especially important for large displays or those installed in outdoor environments where they might be exposed to physical stresses.

5. Adding the Cover

A protective cover or faceplate is then mounted on top of the assembly. This cover can be transparent or tinted and serves to protect the electronic components from dust, moisture, and physical damage.

Besides protection, the cover can enhance the visual quality of the display by diffusing light to reduce glare and improve viewing angles.